In modern supermarkets, convenience stores, and fresh food markets, lighting is no longer a simple “on/off” accessory. It has become a core merchandising tool, directly influencing how products look, how customers perceive freshness, and ultimately, how well items sell.

Nowhere is this more obvious than in refrigerated display cases — multi-deck open cases, glass-door freezers, meat cases, chillers, and dairy coolers.

One of the most important (yet often misunderstood) elements of refrigerated showcase lighting is the optical lens.

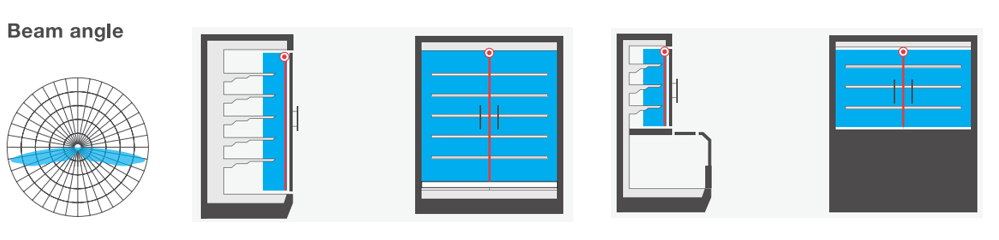

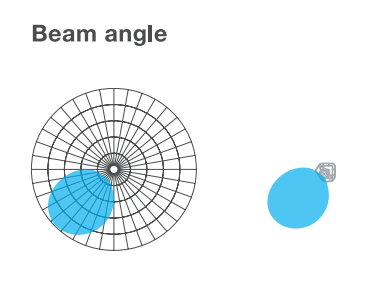

A proper optical design determines where the light goes, how it spreads, and whether it enhances or weakens product visibility.

However, many store owners or equipment manufacturers still consider using standard T8 or T5 LED tubes inside refrigerated displays. While these may work in general room lighting, they cannot meet the unique optical and environmental requirements of refrigerated merchandisers.

This article explains why optical lenses are essential — and why ordinary LED tubes fail in this specialized application.

1. The Unique Lighting Challenges Inside Refrigerated Display Cases

Unlike normal environments, refrigerated showcases have several constraints:

● Narrow, vertical spaces

Shelves block light if it is not directed correctly.

● High product density

Packaging materials reflect light differently — some absorb, some reflect.

● Mixed product categories

Meat, produce, dairy, beverages each require different lighting tones and beam angles.

● Cold, humid environments

Temperature and condensation influence light performance.

● Customer viewing direction

Consumers view products from the front, not from directly below or above.

General LED tubes are not designed with these constraints in mind.

2. What an Optical Lens Actually Does

A professional optical lens is not just a “cover.”

It carefully shapes the light output so the beam lands exactly where it is needed.

A good optical lens can:

✅ Focus light on the merchandise instead of wasting it

A bare LED tube spreads light in all directions — up, down, sideways.

A lens directs light forward toward the products, improving brightness without increasing wattage.

✅ Eliminate dark spots and uneven brightness

Uniformity is crucial.

A well-designed lens ensures each shelf receives even illumination.

✅ Reduce glare and visual fatigue

Direct LED exposure causes harshness.

A lens softens the light while maintaining brightness.

✅ Improve color accuracy (especially for fresh meat, fruits, drinks)

Lens design + high CRI gives more natural, vibrant, and appealing product presentation.

✅ Enhance energy efficiency

Since light is targeted, retailers can use lower wattage while achieving better visual results.

A T8/T5 tube has no optical control, making all the above impossible.

3. Why Standard T8/T5 LED Tubes Fail in Refrigerated Displays

Many store owners try using T8 or T5 LED tubes because they seem inexpensive.

But these tubes were originally designed for general ceiling illumination, not for refrigerated merchandisers.

Here’s why they fail:

1. No Beam Control → Light Wasted Everywhere

A T8/T5 tube emits light 120-220° around, which causes:

- Light hitting the back panel instead of the merchandise

- Strong glare toward the customer’s eyes

- Poor shelf visibility

- Big “dark stripes” under the shelves

As a result, displays look dim, messy, and unprofessional.

2. Poor Shelf Penetration

Refrigerated shelves block light.

Without optical direction, lower shelves receive almost no illumination.

This leads to:

- Dark, unattractive lower shelves

- Reduced visibility for packaged goods

- Lower sales performance

3. Not Designed for Cold, Moist Environments

Most general T8/T5 tubes are designed for indoor conditions, not:

- Condensation

- Constant vibration

- High humidity inside cases

This is why tubes often:

- Flicker

- Lose brightness

- Fail prematurely

4. Bulky Size Limits Installation

T8/T5 tubes are large in diameter and often do not fit properly in narrow showcase channels or shelf edges.

They disrupt airflow and sometimes even interfere with merchandise placement.

4. What Happens in Real Stores When Using Standard Tubes

Retailers who switch from T8/T5 tubes often report:

- Products look dull and flat

- Customers ignore lower shelves

- Videos/photos look flickering online

- Energy bills rise due to higher wattage required

- Frequent replacements due to moisture damage

In contrast, stores using proper refrigerated lighting with optical lenses report:

- Brighter, more attractive displays

- Longer customer engagement time

- Stronger sales conversion

- More even light distribution

- Fewer maintenance issues

- Better performance in store videos (important for social media today)

5. Why Optical Lens Lighting Has Become the Modern Standard

Supermarket lighting requirements have evolved.

Today’s stores focus heavily on video marketing, visual merchandising, and operating cost reduction.

Optical lenses help achieve:

⭐ Professional merchandise presentation

Higher impact = higher sales.

⭐ Energy savings

Targeted light uses fewer watts.

⭐ Longer product lifespan

Better heat management & moisture protection.

⭐ Brand differentiation

A well-lit showcase becomes a “silent salesperson.”

For these reasons, nearly all top refrigeration brands prefer specialized LED strips/tubes with optical lenses — not general-purpose tubes.

Conclusion: Optical Lens = Better Light, Better Sales, Better Store Experience

Refrigerated display cases are a demanding environment where ordinary T8/T5 tubes simply cannot deliver.

Proper lighting must be engineered with:

- Optical beam design

- High CRI

- Moisture protection (IP65+)

- Low-temperature performance

- Directional illumination

This is why optical lenses are no longer optional — they are now the industry standard for professional refrigerated showcase lighting.

-Showcase-300x200.jpg)