気温が上昇すると, アイスクリームが最盛期を迎える. 企業向け, アイスクリームは利益点と損失の両方を表します。 “被災地。” 研究によると, 以上のストレージ アカウントが間違っています 30% アイスクリームの損失のうち. アイスクリームはまだ賞味期限内ですが、, 表面に氷の結晶が発生し、パッキンに付着します。, 有効期限が切れていない製品の商業的価値が早期に失われる結果となる. 多くのアイスクリーム会社は、製品の賞味期限を延ばすために温度を下げています。, しかし、電気料金の高騰にも直面している. これらの問題の原因は、予期せぬ細部に隠されている場合があります: 冷蔵庫の照明システム.

アイスクリームの保存温度

アイスクリームの最も重要な保存原則は、一定の温度を維持することです, 通常は-18℃以下

気温が3℃上がると, アイスクリームの賞味期限は次のような理由で短くなる可能性があります。 50%. 冷凍庫のドアが頻繁に開くとき, 外部の暖かい空気が急速に侵入します, キャビネット内の温度変動を引き起こす. これにより、アイスクリームの表面が凍結と融解のサイクルを繰り返します。, 氷の結晶の形成を促進し、食感を損ない、細菌増殖のリスクを生み出します。. これは、単純に温度を下げるだけでは表面の氷晶の問題を解決できない理由を説明しています。 –根本的な原因は、強引な冷却ではなく、安定したコールド チェーンの整合性を維持することにあります。.

冷蔵ディスプレイライトの温度がアイスクリームの品質に影響を与える理由

現代の商業環境において, 冷蔵陳列照明は基本的な照明機能を超え、サイレントセールスのエキスパートになりました. コールドチェーン機器メーカー向け, プロのアイスクリーム照明ソリューションは、製品提供に大きな価値を加えることができます. その間, 小売業者向け, プロ仕様の LED ライトは、冷凍おやつの賞味期限を延長するだけでなく、エネルギーコストも削減します。. さらに重要なことです, 照明は製品をより鮮やかで魅力的なものにする可能性があります, 顧客の滞在時間を延長する, 売上の成長を促進する; 消費者向け, プロ仕様の照明は快適なショッピング環境を提供し、全体的な購買体験を向上させます。.

食品安全基準を満たす冷蔵ショーケース照明の選び方

1. 見た目に騙されないようにする. 照明の選択が明るすぎて寒い, アイスクリームの見た目が悪くなり、視覚疲労を感じやすくなります。. CRI を持つライトを使用することをお勧めします > 90 色温度3000K~4000Kの温白色光でアイスクリームの外観を向上させます。.

2. エネルギーの節約. 低電圧ランプとランタンは、消費電力が少ないため、間違いなく最良の選択肢です。, 安全です, 従来の T8 チューブを 24V 低電圧に置き換えます。.

3. 照明器具を選ぶときは, コストだけが決定要因であってはなりません. を避けてください。 “低価格優先” 考え方, 多くのノーブランド照明製品には品質保証がありません. これらの備品は損傷しやすいです, 高レベルのエネルギーを消費する, 頻繁な交換による隠れたコストがあり、見積もることが困難です.

アイスクリーム照明ソリューション

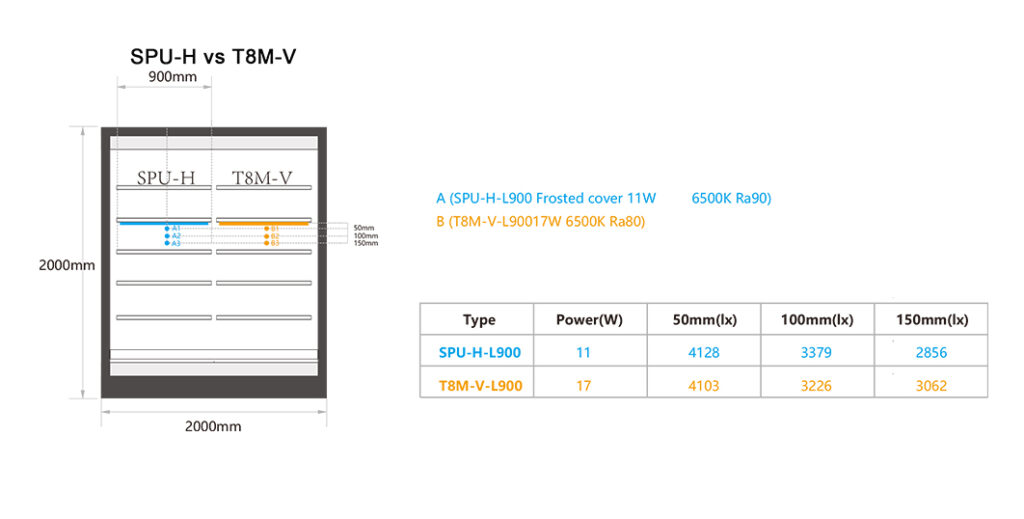

アイスクリーム照明システム用, レイディシャインSPUシリーズ 革新的なソリューションを提供します

1. 最先端のレンズテクノロジーを搭載したSPUシリーズ, 迷光を発生させることなく製品表面に光を正確に集束させることが可能. Ra90+の高演色評価数, 商品の魅力的な質感を効果的に演出する冷蔵ショーケースライトです。.

2.24V 低電圧設計, 内蔵アルミニウム, 良好な放熱性, 典型的なものと比較して T8チューブ, 35% 省エネ

3. 独自の正三角形デザインにより2つの取り付け面が可能, 効率を高めるために光の角度を変更することもできます.

4. 磁石とネジの両方の取り付けオプションをサポートする 2 種類のブラケットを設計しました。. 将来のライト交換に備えて, ユニット全体を取り外す必要がなく、ブラケットを開けるだけで固定具を交換できます。, 時間と労力を大幅に節約.

5. Laidishine はマルチデッキショーケース用のワイヤー/ハーネスシステムをアップグレードしました. 保存 40% 時間と労力の.

よくある質問

Q: 冷蔵ショーケースの照明に必要なルーメン出力はどれくらいですか?

あ: 設定することをお勧めします 800-1200 レール1メートルあたりのルーメン, キャビネットの奥行きに応じて配光カーブを調整.

Q: 照明器具はどれくらいの頻度で交換すべきですか?

あ: 高品質の LED 冷蔵ショーケース ライトの寿命は 50,000 時間以上です。. 光効率テストを毎回実施することをお勧めします。 3 年.

Q: 投資収益率を評価する方法 (ROI) 照明改修用?

あ: ケーススタディが示す:

電気代の節約: 1.2円/日/筐体

損失の削減: 5.6円/日/筐体

回収期間: <8 数ヶ月

クリックして当社の Web サイトにアクセスし、マルチデッキのオープン/クローズおよびアイランド キャビネット アプリケーション向けのソリューションを探索してください。.